Hv Transformer Winding

Electricalindia in go back to transformer fault conditions 4.

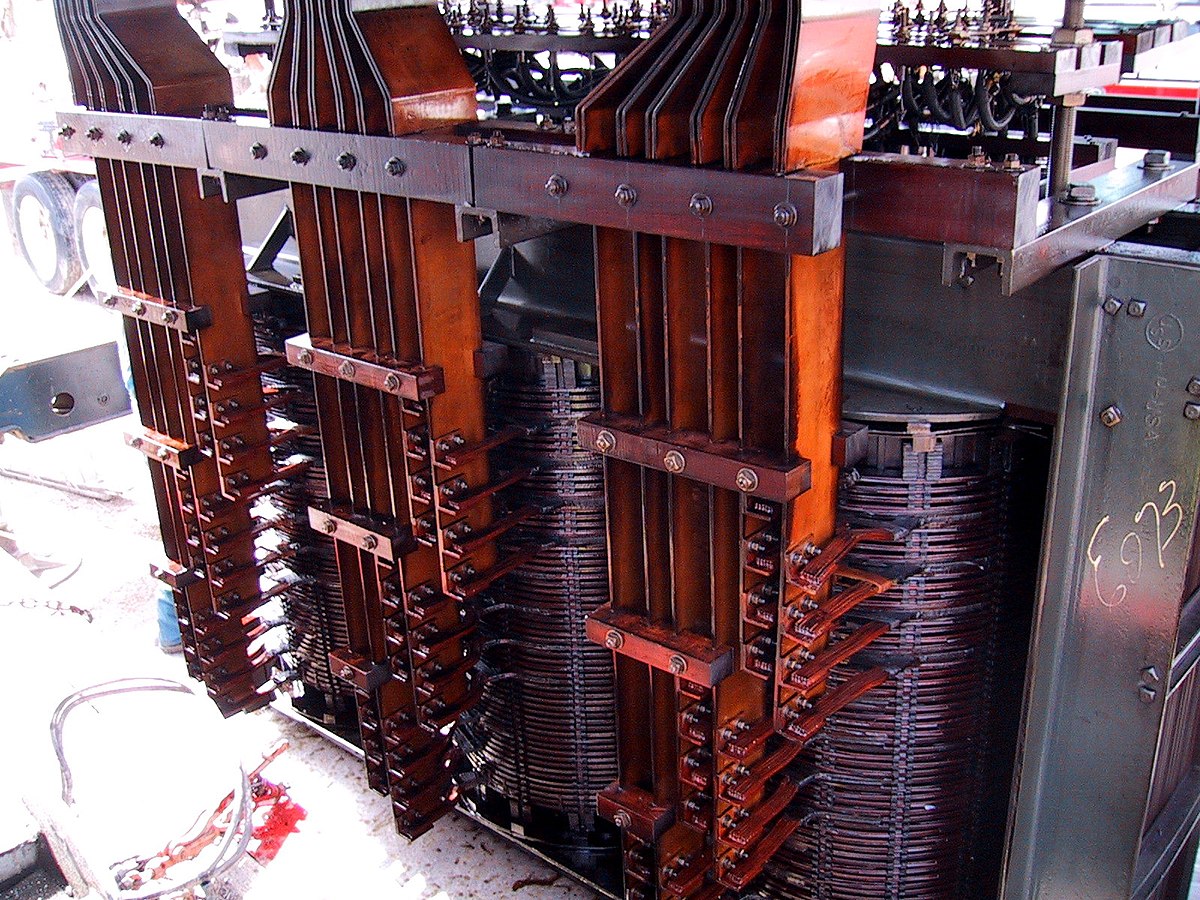

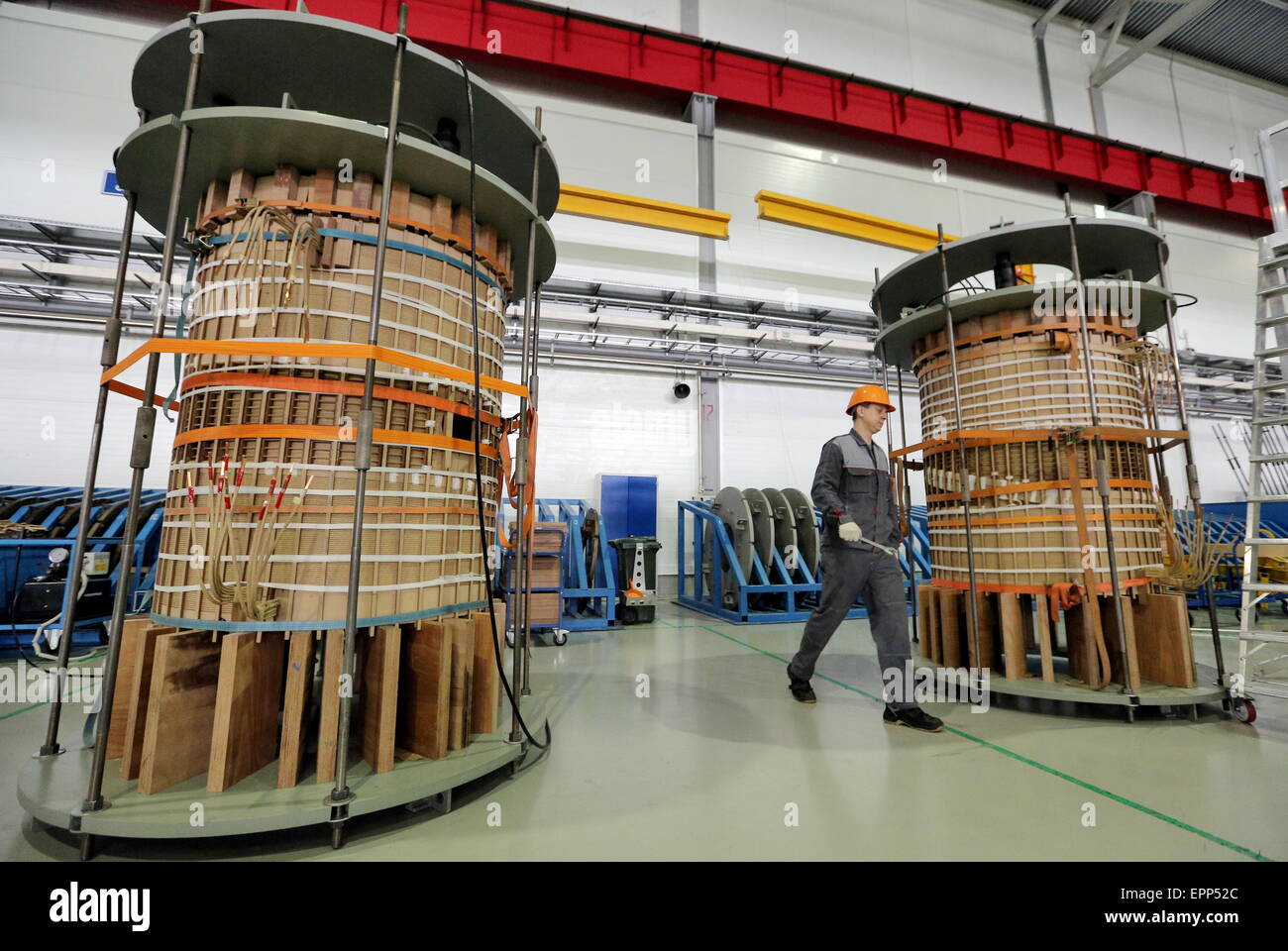

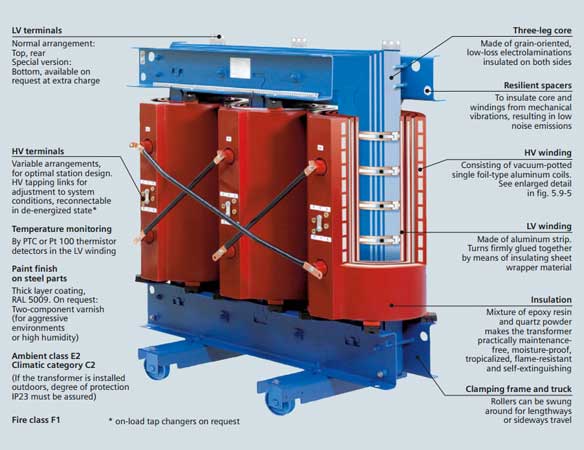

Hv transformer winding. The maximum number of strips used in parallel to make up a conductor. Copper and aluminum are the primary materials used as conductors in power transformer windings. The windings consist of the current carrying conductors wound around the sections of the core and these must be properly insulated supported and cooled to withstand operational and test conditions. Heat rise cooling curve.

The 2293 performs the measurements on both steps. In this case induced voltage waveform in the secondary winding will be in phase with the applied voltage waveform. The terms winding and coil are used interchangeably in this discussion. The main aim of transformer is to stepup or stepdown the voltage.

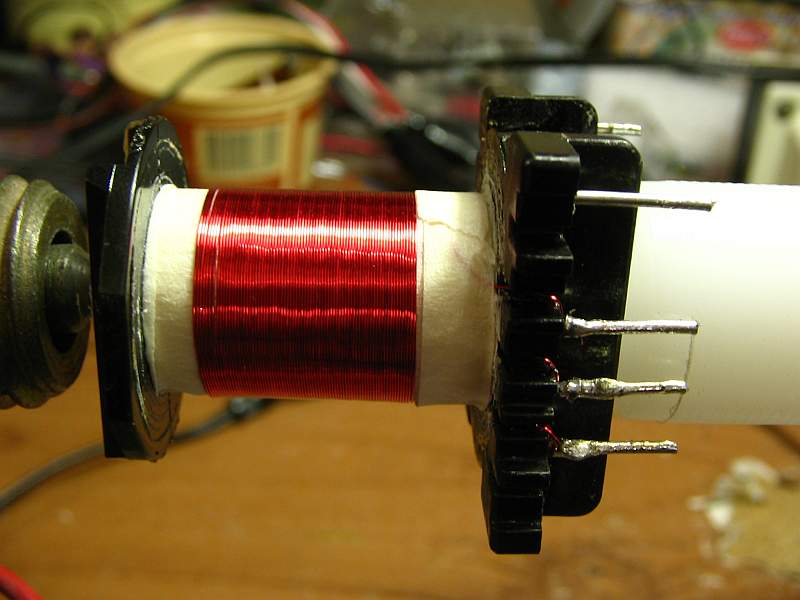

High voltage transformers can be high voltage windings or high voltage isolation between windings or both. We use helical windings low voltage high capacity transformers where the current is higher at the same time windings turns are lesser. Before conducting a transformer winding resistance test it is important to observe all safety warnings and take proper precautions ensure that all equipment to be tested is properly grounded and treat all high voltage power equipment as energized until proven otherwise by using the proper lockout tagout procedures. Use caution when testing.

The output of the transformer varies from 160 1000 kva from 0 23 15 kv. For the heat rise optional connection of the. One end of the high voltage or secondary winding of second transformer is connected to the earth and other end alone comes out from the high voltage bushing for feeding high voltage to the equipments and insulators under testing. Interturn faults occur due to winding flashovers caused by line surges.

If the windings of the two coils of a transformer are wound in the same direction the applied voltage and the induced voltage will have the same direction in both the windings. L c magnetics can manufacture high voltage transformers up to 20 kv of winding voltage or 20 kv of isolation voltage. It monitors the transformer temperature during the heat rise and measures hv and lv side resistances simultaneously during the cooling curve. So if you give some input on one of the windings you will receive output voltage on other side of windings.

When transformer is disconnected and winding resistance is measured. The 2293 is an automatic winding analyzer optimized for three phase power and distribution transformer measurements. Figure 2 transformer interturn fault photo credit. To secure adequate mechanical strength the cross sectional area of the strip not made less than 75 100 mm square.

It uniquely combines winding resistance measurement turns ratio measurement core demagnetization transformer type detection magnetic balance and heat run test temperature rise and cooling curve in the fastest single instrument solution on the market.